The refrigerant gas is discharged from the compressor to the inlet connection of the KEN evaporative condenser. The water in the condenser pool circulates over the condenser coil while drawing in the ambient air flow. The evaporation process cools water jets, which in turn cool pipes containing refrigerant gas. The cold wall causes the refrigerant gas to release heat and condense into a liquid. The condensed liquid flows out of the coil to the high pressure liquid receiver to return to the system. The hot, saturated discharge air is drawn through the dehydrator and released into the atmosphere. The unevaporated water falls into the sump and is recirculated to the distribution system above the condensate coil section.

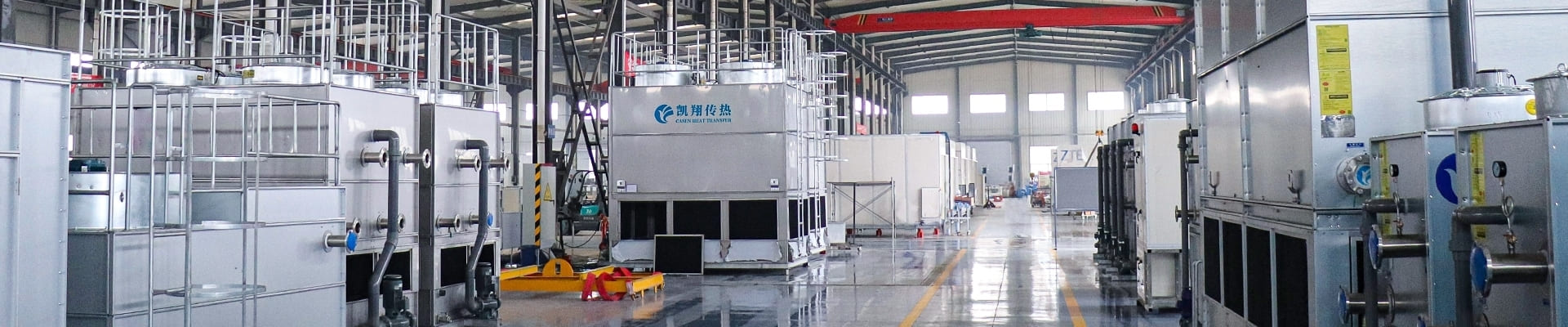

Countercurrent Evaporative Condenser

Rational design

Reasonable piping and optimized design parameters make the flow resistance of the fluid controlled within the range of technical requirements.

More compact structure

No packing design is adopted to reduce packing space;

The equipment structure is more compact, occupying less space;

Easy to install, easy to operate and maintain.

Elliptic tube design

Elliptic tube design can be selected to effectively improve the change efficiency;

With low wind resistance, high wind speed, low energy consumption;

Use less refrigerant, increase water load, reduce costs;

Tighter arrangement, more compact structure.