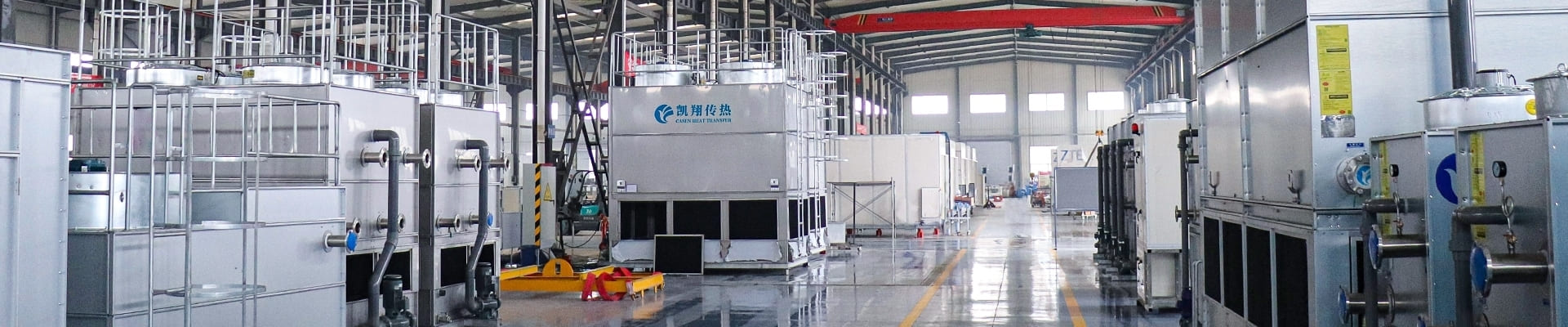

KEJ series efficient composite evaporative air cooler is based on the working principle of thermodynamics and heat transfer, using the heat exchange mechanism of evaporative air cooler and air-cooled condenser, using the mixed flow technology of surface heat exchange and the energy-saving technology of cascade heat exchange, is the latest generation of high-tech, high-performance and high-quality heat exchange equipment.

In the KEJ evaporative condenser, the finned tube unit is located above the water remover and below the fan. The process gas first passes through the finned tube unit and then through the coil section below. A portion of the load is dissipated into the atmosphere through sensible heat transfer at the finned tube unit through the tube walls and fins, so less heat needs to be expelled in the coil section, which means less water evaporates. In this process, the gas is condensed into a liquid. Water is pumped from the bottom pool and sprayed onto the coils below. At the same time, the axial fan introduces ambient air to the surface of the coil and the surface of the finned tube. On the surface of the coil, enough latent and sensible heat is exchanged between air and water to allow the process gas to release heat and condense into a liquid. The hot saturated air is then inhaled through the dehydrator and the finned tube, and the possible smoke plume is attenuated by the finned tube and then discharged into the atmosphere. Unevaporated water falls into the basin and re-enters recycling.