The fluid flows in the coil, the outer wall of the coil is covered by spray water, the heat of the fluid is transferred through the tube wall, forming saturated wet and hot steam with water and air, the heat is discharged into the atmosphere by the fan, the water is blocked back to the collection tank circulation spray, the spray water reduces the water temperature through the PVC heat sink in the process of circulation, and the fresh air is sucked into the transverse window on both sides of the tower body. Heat is exchanged with the spray water after heat exchange to reduce the spray water temperature. The coil mainly relies on sensible heat conduction. This model is suitable for air conditioning projects with strict noise requirements and temperature difference Δt=4-15℃ and other conventional industrial applications.

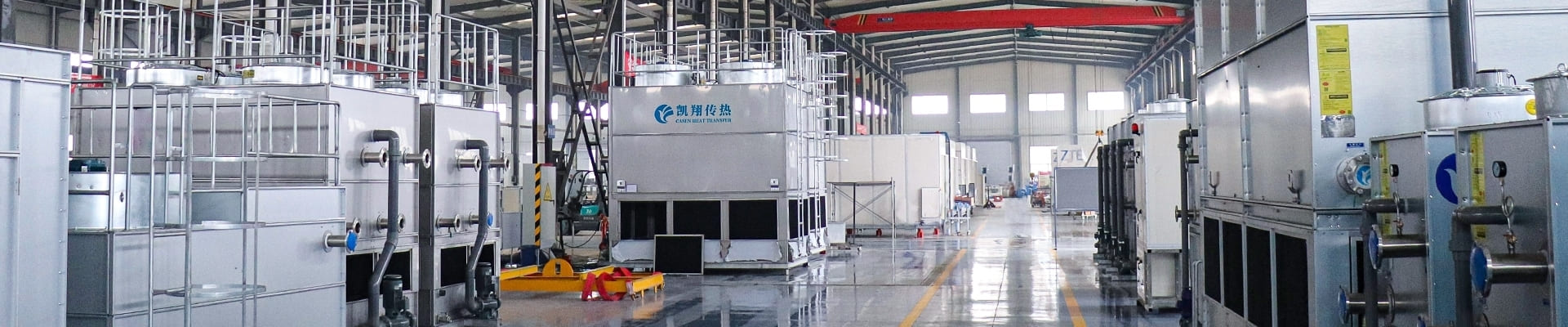

Cross Flow Type Closed Cooling Tower

Feng shui in the same direction, excellent heat exchange performance

The KCF series uses the combined technology of coil and PVC packing for secondary heat exchange in fengshui co-flow to achieve efficient heat exchange performance. At the same time, it can effectively reduce the formation of pipe wall scale. Air and spray water flow through the coil at the same time, so that the spray water covers the surface of the coil to the maximum extent, ensuring that the surface of the coil is completely wet. Compared with the countercurrent tower, the formation of scale on the wall of the coil is greatly reduced.

Packing design, reduce coil volume, reduce cost

Packing design greatly improves the spray heat transfer efficiency, reducing air volume requires more energy saving. The spray water reduces the water temperature through the PVC heat sink (filler) in the process of circulation, forming a feng shui lateral flow with the fresh air, and the coil mainly relies on the spray water for heat exchange, the lower the spray water, the better the cooling effect. An important feature of this operating principle is the maximum possible reduction in coil volume, thus reducing costs.

High efficiency heat exchange table cooler (multiple types/materials optional)

Round coil: Round coil, durable, low water resistance, inclined design to facilitate material discharge, coil pressure is low.

Efficient heat transfer oval tube: improve the interface between air and water in the pipeline, increase the effective contact area by 40%, and improve the heat transfer efficiency.

Nodal tube: Concave and convex waves are added inside and outside the tube, and strong turbulence is formed inside the fluid, while greatly increasing the contact area of hot and cold fluids.

Large maintenance space

Large maintenance space, maintenance doors and channels, spacious internal space, maintenance personnel can easily carry out various maintenance work in the interior, more convenient maintenance.