In a compound closed cooling tower, the finned tube unit is located above the water remover and below the fan. The process liquid first passes through the finned tube unit and then through the coil section below. A portion of the load is dissipated into the atmosphere through sensible heat transfer at the finned tube unit through the tube walls and fins, so less heat needs to be expelled in the coil section, which means less water evaporates. In this process, the high-temperature liquid is pre-cooled. Water is pumped from the bottom pool and sprayed onto the coils below. At the same time, the axial fan introduces ambient air to the surface of the coil and the surface of the finned tube. On the surface of the coil, enough latent and sensible heat is exchanged between air and water to allow the process liquid to release heat and cool down. The hot saturated air is then inhaled through the dehydrator and the finned tube, and the possible smoke plume is attenuated by the finned tube and then discharged into the atmosphere. Unevaporated water falls into the catchment tank and is re-entered for recycling.

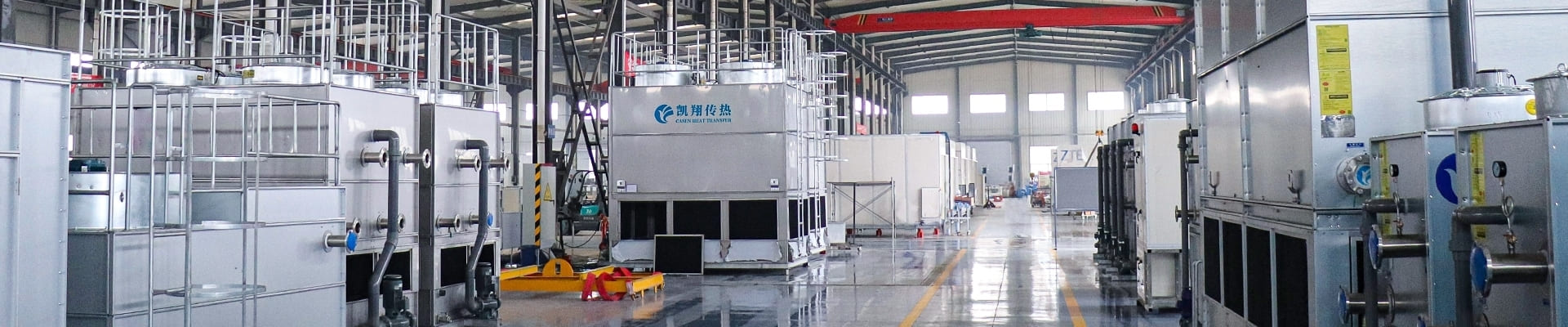

Compound Type Closed Cooling Tower

Rational design

Reasonable piping and optimized design parameters make the flow resistance of the fluid controlled within the range of technical requirements.

More compact structure

Counterflow tower products are compact, compared with more coil cooling area layout, more suitable for low temperature cooling projects with small temperature differences. Save more space to increase the heat dissipation area and reduce the footprint.

No packing design is adopted to reduce packing space;

The equipment structure is more compact, occupying less space;

Easy to install, easy to operate and maintain.

Precooled fin design

The pre-cooling fin design is added at the top to avoid the phenomenon that water is easy to scale at high temperature, so that the heat load per unit area of the evaporative heat exchange parts is significantly increased, and the service life of the equipment is extended; Greatly achieved the effect of water saving and energy saving, especially suitable for serious water shortage areas.

High efficiency heat exchange table cooler (multiple types/materials optional)

Circular coil

Round coil, durable, low water resistance, inclined design to facilitate material discharge, coil pressure reduction.

High efficiency heat exchange oval tube

The heat transfer efficiency is improved and the maximum unit area capacity is increased, the effective contact area is increased by 40% compared with the circular tube, and the wind resistance is low, the wind speed is high, the energy consumption is low and the cost is low.

Nodal tube

Concave and convex waves are added inside and outside the tube, and strong turbulence is formed inside the fluid, and the concave and convex structure greatly increases the contact area of cold and hot fluids.