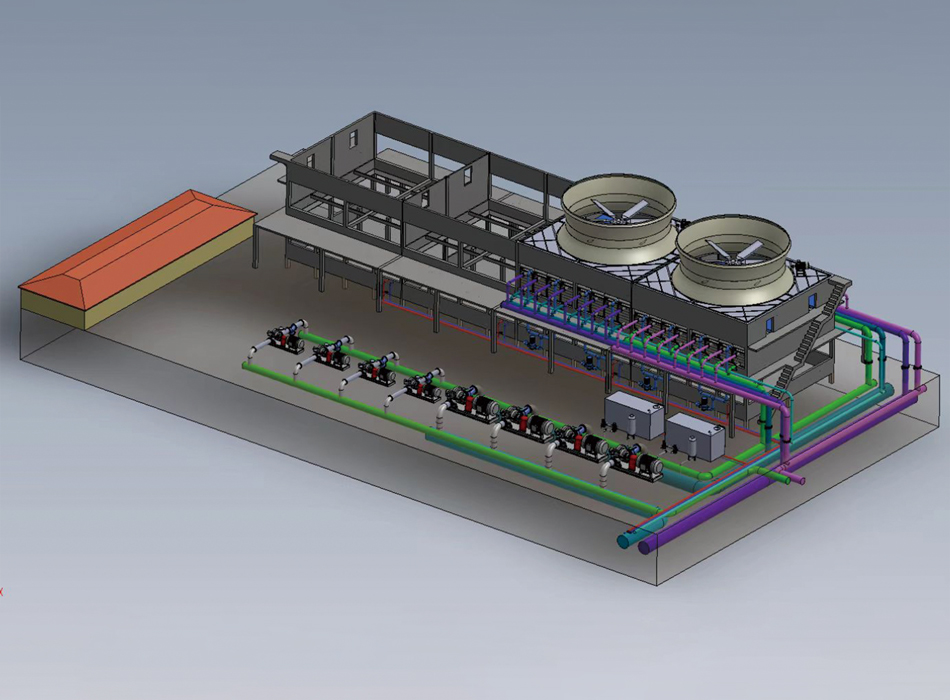

Taking the typical integrated dry and wet combined heat exchange station as an example, its structure generally adopts the type of air cooling tower and evaporative wet cooling tower in series, that is, the high temperature circulating water first enters the air cooling tower for dry air cooling, and then enters the evaporation section through the series pipeline to continue cooling to meet the process requirements. The air cooling tower uses ambient air to cool the circulating water through the heat exchange element, because the air density is low, the heat transfer coefficient is small, so it is usually through the fin expansion area to strengthen the heat transfer effect, so the heat exchange element is generally used bimetal fin tubes, such as stainless steel tubes in the base pipe, and aluminum fins are used in the fin. The evaporative wet cooling tower is to strengthen the air side cooling heat transfer by spraying water outside the heat exchange element, and the evaporative cooling heat transfer coefficient is high, so the heat transfer element is generally made of metal heat exchange tube, and the shaped tube can also be used to strengthen the heat transfer, such as 304 wave joint tube and 304 oval tube.

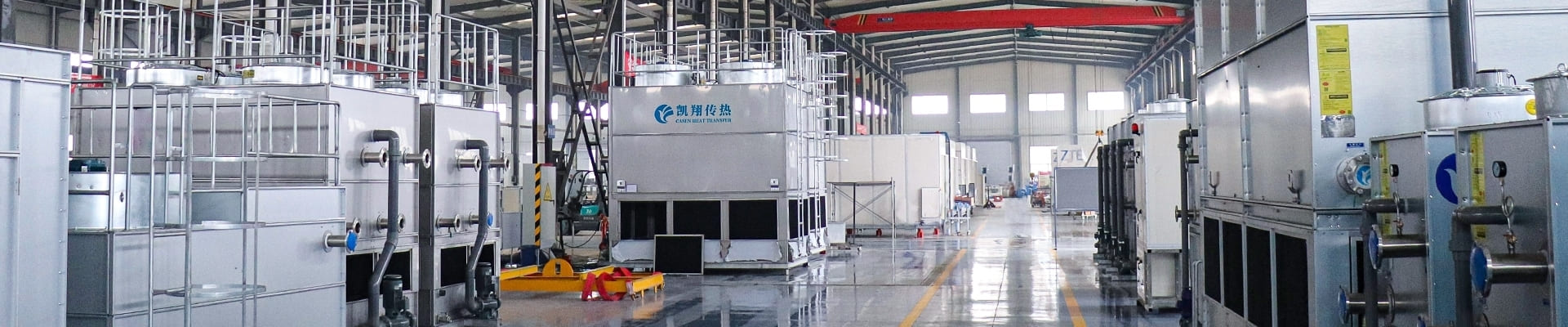

Integrated Heat Exchange Station

Cooling tower heat transfer capacity is sufficient

CTI certifies products. Our cooling towers are advanced in design and offer users a wide range of operational and performance advantages. The product has passed CTI certification, and its performance is 100% up to the standard. The selection of products has a margin to meet 100% of the user's heat dissipation requirements.

High efficiency oval tube heat exchanger table cooler

Efficient oval tube heat exchanger cooler, effectively improve the heat transfer efficiency, oval design can effectively increase the water load, save costs. The overall arrangement is tighter, the layout is reasonable, and the wind resistance is smaller. (Multiple design options for circular and elliptical tubes).

Automatic control

PLC intelligent control unit, automatic adjustment, intelligent alarm. Can provide customized control cabinet, more convenient and intelligent, recognize the temperature signal to start or close the corresponding motor/fan, to achieve economic operation and save energy.

Strict factory inspection

Sound ISO quality management system, strict factory testing process (strict condenser pressure test, electronic control system testing, equipment trial operation, etc.), to ensure that the equipment is in line with the standard.

Customize products according to field conditions

Anti-freezing design;

Low noise design;

Coil multi-material options - hot dip zinc carbon steel pipe/stainless steel pipe/copper pipe;

Fan: frequency conversion/non-frequency conversion control; Various materials of wind ducts and blades are available.

Modular design

Structured box design, reduce the amount of on-site engineering installation;

Compact structure, light weight, convenient layout;

Under strict quality control conditions, assembled from standard parts;

High strength magnesium aluminum zinc plate, easy to disassemble, simple maintenance.